Before installing a muffler intake, thoroughly inspect your vehicle's exhaust system for seamless integration. Check alignment, pipe transitions, mounting hardware, and cat back system condition. Ensure proper sealing, gaskets, seals, and air filters during installation for optimal performance. Align exhaust components for smooth gas passage, enhancing speed and fuel efficiency while maintaining environmental compliance.

When undertaking a muffler intake installation, ensuring optimal performance requires meticulous attention to several key mechanics. First, assess exhaust system components for compatibility to avoid leaks or damage. Next, verify mounting hardware and bracing integrity, as these elements bear the brunt of strain. Lastly, ensure proper sealing and gas flow optimization to maintain engine efficiency and reduce noise pollution. By meticulously checking each of these aspects, you guarantee a safe and effective muffler intake installation.

- Assess Exhaust System Components for Compatibility

- Verify Mounting Hardware and Bracing Integrity

- Ensure Proper Sealing and Gas Flow Optimization

Assess Exhaust System Components for Compatibility

Before initiating any muffler intake installation, it’s paramount to meticulously examine all components within your vehicle’s exhaust system for seamless integration and optimal performance after the upgrade. Compatibility checks are crucial to avoid potential issues such as leaks or misalignment that could negate the benefits of a high-performance exhaust, like those featuring advanced designs or durable materials.

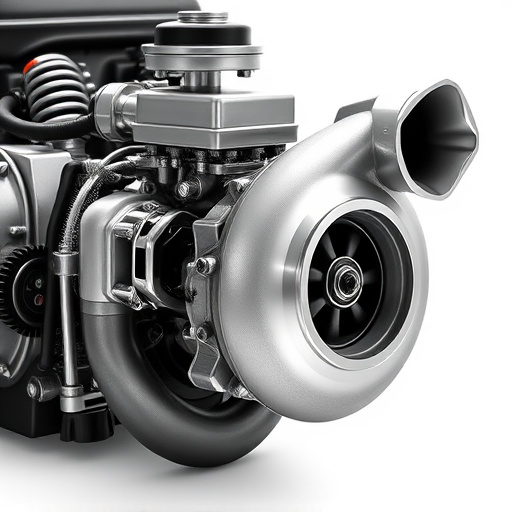

This involves scrutinizing elements like exhaust tips, which serve as terminations for the system, ensuring they align correctly with the vehicle’s structure and don’t interfere with other parts like brake rotors. Similarly, assessing the overall length, diameter, and angle of the exhaust pipes guarantees a smooth transition from the engine to the muffler, enhancing both sound quality and engine performance.

Verify Mounting Hardware and Bracing Integrity

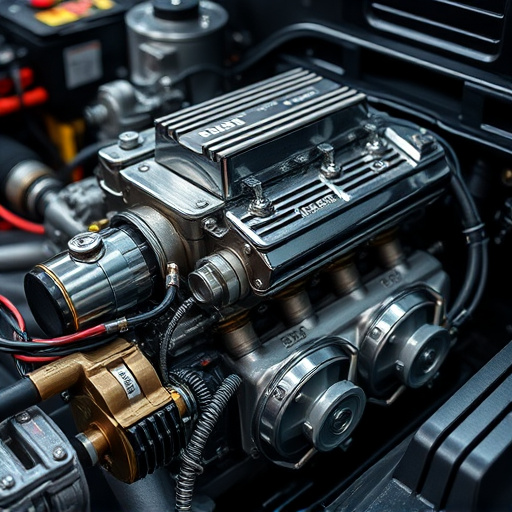

When undertaking a muffler intake installation, verifying the mounting hardware and bracing integrity is a critical step. This involves checking all bolts, brackets, and pipes to ensure they are securely fastened and in optimal condition. Any signs of corrosion or damage should be addressed before proceeding, as these issues can compromise the structural integrity of your vehicle’s underbody and affect performance.

Furthermore, inspecting the alignment and stability of intake components is essential for a successful muffler intake installation. Ensure that cold air intakes are correctly positioned to draw in un contaminated air from the desired source, typically outside the engine bay. This guarantees optimal airflow, enhancing engine performance and efficiency. In addition, verify the condition of the cat back exhaust system to ensure it’s seamlessly integrated with the new muffler intake, promoting smooth operation and minimizing noise levels.

Ensure Proper Sealing and Gas Flow Optimization

During muffler intake installation, achieving proper sealing is paramount to prevent leaks that could compromise both performance and environmental standards. This involves meticulously inspecting gaskets, seals, and connections for any signs of wear or damage. A well-sealed system ensures that gases flow seamlessly from the engine into the exhaust mufflers, maximizing efficiency and minimizing noise pollution.

For optimal gas flow optimization, consider the role of performance air filters in allowing clean, high-flow air to enter the engine. Ensuring these filters are in top condition complements the overall effectiveness of the muffler intake system. Additionally, aligning the exhaust system components, including brake rotors where applicable, is crucial for smooth gas passage, thereby enhancing both vehicle speed and fuel efficiency.

During a muffler intake installation, ensuring proper functionality involves several key checks. After assessing the compatibility of exhaust system components and verifying mounting hardware integrity, it’s crucial to focus on sealing and gas flow optimization. By meticulously examining these aspects, you guarantee not only a seamless fit but also enhanced engine performance and reduced emissions, making your muffler intake installation a successful and efficient process.